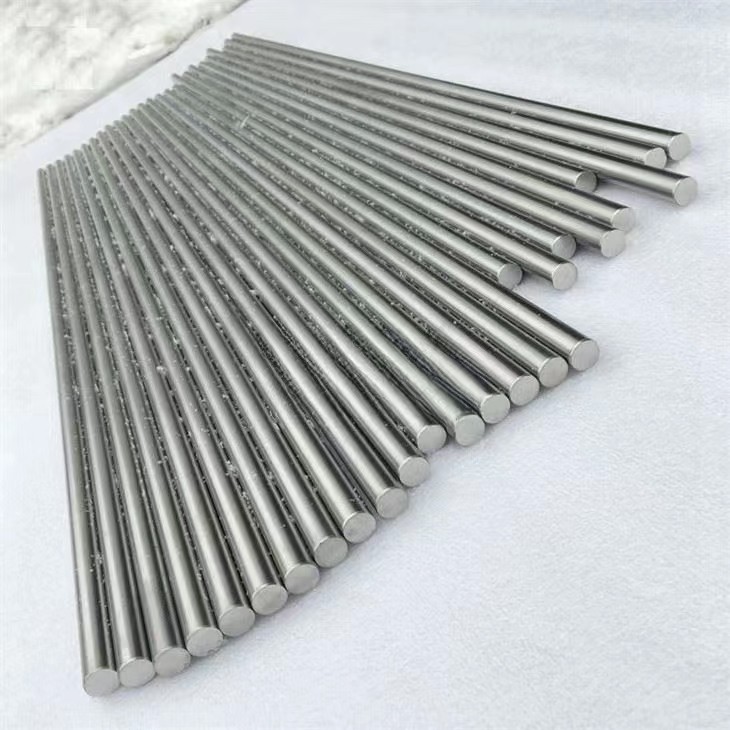

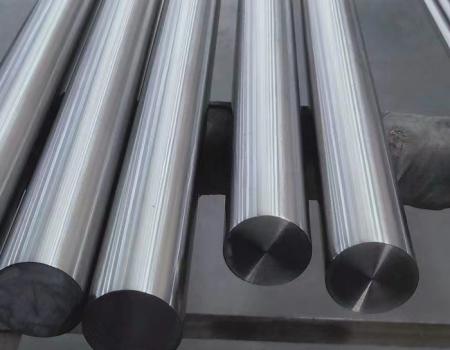

Pure Titanium Bar or industrial Pure Titanium Bar or commercial Pure Titanium Bar, is classified according to the content of impurity elements. It has excellent stamping process performance and weldability, is insensitive to heat treatment and microstructure type, and has certain strength under satisfactory plastic condition. Its strength mainly depends on the content of interstitial elements oxygen and nitrogen.

Chemical Composition

Tensile Requirements

Grade characteristics and application fields of pure titanium

→Gr1

GR1 titanium is the first of four grades of industrial pure titanium. It's the softest and most malleable of these grades. It has maximum formability, excellent corrosion resistance and high impact toughness.

Because of all these qualities, GR1 is the preferred material for any application requiring easy formability, and is usually used as titanium plate and tube. These include:

chemical treatment

Chlorate manufacturing

Size stable anode

Desalination

Architecture

Medical industry

Marine industry

Auto parts

Fuselage structure

→Gr2

Because of its diverse availability and wide range of availability, Gr2 titanium is known as the "main force" of commercial pure titanium industry. It has many of the same qualities as GR1 titanium alloy, but slightly stronger. Both are equally resistant to corrosion.

It has good weldability, strength, ductility and formability. This makes Gr2 titanium rods and plates the first choice in many applications:

Architecture

electricity generation

Medical industry

Water carbon processing

Marine industry

Exhaust pipe shield

Fuselage skin

Desalination

chemical treatment

Chlorate manufacturing

→Gr3

This grade uses at least commercial pure titanium grade, but this does not reduce its value. GR3 is stronger than GR1 and Gr2, has similar ductility and only slight formability - but it has higher mechanical properties than its predecessors.

Grade GR3 is used in applications requiring medium strength and major corrosion resistance. These include:

Aerospace structure

chemical treatment

Medical industry

Marine industry

→Gr4

GR4 is considered to be the strongest of the four commercially pure titanium. It is also known for its excellent corrosion resistance, good formability and weldability.

Although it is commonly used in the following industrial applications, recently grade 4 has found a niche for medical grade titanium. It is needed in applications that require high strength:

Fuselage components

Cryogenic vessel

Heat exchanger

CPI equipment

Condenser tube

Surgical hardware

Pickling basket

Welcome to send an inquiry to mira@xjcmetal.com at any time if you need.

Hot Tags: pure titanium bar, China, suppliers, manufacturers, factory, customized, wholesale, buy, price, quotation, in stock, for sale, Titanium Forgings, Ti Equipment, Medical Titanium Strip, Gr 11 Titanium Forged Ring, Titanium Sheet Plate, Medical Gr23 Titanium Bar

Sputtering-Target.44.1.png)