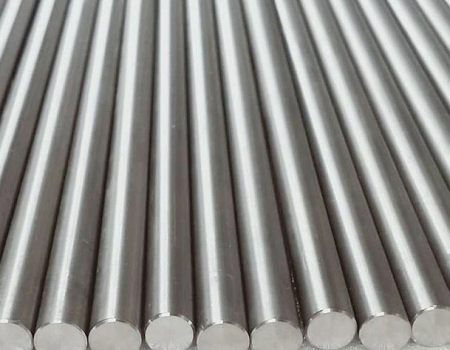

High-Strength Titanium Filler Rod is the strongest of all the titanium alloys . It offers a versatile mix of good corrosion resistance, weldability, and formability. It's often used for turbine blades, fasteners, and spacer rings.

For the titanium bars, the below sizes are available.

Diameter: 1.0-300mm

Length: 6000mm max

We stock a wide range of titanium rods, including a complete commercial line and medical titanium rod. Titanium connecting rod, titanium rod in the femur, titanium welding rod, titanium filler rod, titanium threaded rod, and nitinol rod are all available. It can be supplied in random lengths or cut into fixed lengths, according to your precise dimensions.

Titanium is highly resistant to chloride-containing media, practically all salt solutions, seawater, a range of acids, organic and inorganic chemicals, and gases. The high environmental resistance is primarily based on a very thin, tenacious, and highly protective surface oxide film. The oxide film provides high resistance to erosion in high-velocity process streams. It is non-magnetic and characterized by a high melting point, high strength-to-weight ratio, and a low modulus of elasticity.

Titanium Rod Specifications

Chemical Requirements of Titanium Rod (Nominal %)

Mechanical Requirements of Titanium Rod

Welcome to send an inquiry to mira@xjcmetal.com at any time if you need.