We provide high performance specialty metals for critical applications in the aerospace market including commercial airframes, engines, internal and external systems, military and defense, rotary wings, space, and many other applications.

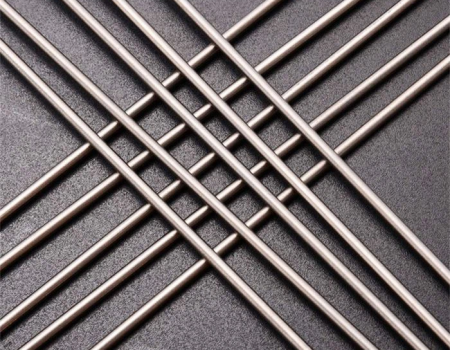

Titanium bar for Aerospace Standard:AMS 4928, AMS4911

Aerospace; containing about Titanium bar for Aerospace and forgings

Classification Titanium and titanium alloys

Performance corrosion resistance

Density :4.51 g/cm3

We uses a 800T forging hydraulic press for heating forging. This process internally changes the structure of the product and improves the physical properties of the product.

Quality control: ISO9001:2015 100% ultrasonic flaw detection, entrust a third party to carry out physical and mechanical properties, high magnification metallographic inspection.

Chemical element content(%)

Mechanical behavior

As new Titanium products, alloys and manufacturing methods are employed by the aircraft industry, the use of titanium will expand in this application.

The selection of titanium in this application is a result of the specific properties associated with the metal including:

strength to weight ratio

reliability

corrosion resistance

mechanical properties

thermal expansion

location on the galvanic series

XJC metal Aerospace provides global service center inventories at competitive prices, guaranteed quality and the best delivery available to all levels of the aerospace supply chain. We are a privately held business with a long-term growth plan and a quick decision making process. XJC metal stands ready to partner with you and to support aerospace programs around the world.

Quality Assurance:

—-According to globally recognized standards, such as ASTM, AMS, ASME,JIS,MIL…

—- provide third-part inspection reports.

Firstly: Visual inspection to check surface quality, ensuring without flaw, black dot and any other defects.

Secondly: Ultrasonic Flaw Detection making sure there are no defects inside.

Thirdly: Chemical Composition making sure all chemical components can satisfy customer’s demands

Fourthly: Mechanical Property testing making sure all titanium bars have satisfying mechanical features before delivery.

—–Chemical composition, Mechanical properties, Micro-structure is strictly controlled,

—–ISO Quality Management System

—–Third party test like SGS before shipment

Welcome to send an inquiry to mira@xjcmetal.com at any time if you need.