Medical Titanium Bar for Bone Spicule Executive standard: GB/T 13810-2007, ASTM F67, ASTM F136 1、The ingots used for the production and processing of materials shall be smelted in a vacuum consumable electric arc furnace or EB furnace smelting and vacuum consumable electric arc furnace smelting, and the number of smelting shall not be less than twice. 2、The H content in pure titanium, TC4 and TC4ELI should not exceed 0.010%。

Executive standard: GB/T 13810-2007, ASTM F67, ASTM F136

The ingots used for the production and processing of materials shall be smelted in a vacuum consumable electric arc furnace or EB furnace smelting and vacuum consumable electric arc furnace smelting, and the number of smelting shall not be less than twice.

1. The chemical composition of the product meets the requirements of the corresponding brand in GB/T3620.1, and the H content in pure titanium, TC4 and TC4ELI should not exceed 0.010%. When the buyer re-inspected, the allowable deviation of chemical composition should meet the requirements of GB/T3620.2.

2. Dimensions and allowable deviations The dimensions of the product should be measured with corresponding precision measuring tools, and the positive and negative tolerances should be guaranteed according to customer requirements.

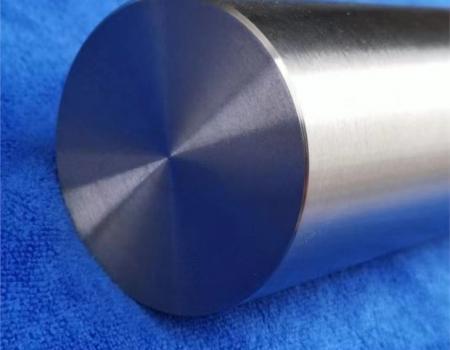

3. High and low magnification tissue inspection shall be carried out in accordance with the provisions of GB/T5168. Medical titanium rods and medical titanium alloy rods are not allowed to have cracks, pores, metal or non-metallic inclusions and other visual defects on the transverse low power. The annealed state of the pure titanium rod should have a uniform transverse microstructure, and the grain size should not be coarser than grade 5. The high-magnification structure of the medical titanium alloy rod in the annealed state should conform to A1~A9.

Size:φ45 ~φ65mm

Length:800-3000mm and according to customer’s requirement

Grade:GR5、Ti-6Al-4V、Ti-6Al-4V ELI、 Ti-6Al-7Nb 、TC20

Standard:GB/T13810-2007 、 ASTM F1295、 ASTM F136、ASTM F1295 ISO5832-3、ISO5832-11

Tolerance :h9-h11 (0,+0.3)mm

Straightness :0.5MM/M

Surface:bright, lathe, rolled

Quality control

Baoji Chenyuan Metal Material Co., Ltd have been got the ISO13485:2003;ISO9001:2003 Certification, and strict according to modern enterprise management system to control raw material, production process, finished product inspection control , make the product traceability and steady.

Package details:

1)Standard wooden cases with plastic bags inside.

2)Three-ply or plywood,fumigation-free.

3)as the clients requirement.

Specification:

High tensile strength、nice flexible、small tolerance、 better straightness 、metallographic structure、High wearability、bone matrix gelatin

Medical titanium bar for implants is need tensile strength is up to 1050 Mpa ,the metallographic structure is below A3 .

For more information on Medical Titanium Bar for Bone Spicule, please contact us.

Email: mira@xjcmetal.com

Hot Tags: medical titanium bar for bone spicule, China, suppliers, manufacturers, factory, customized, wholesale, buy, price, quotation, in stock, for sale, erti 2 titanium wire, ASTM B265 Gr7 anti corrosion titanium plate sheet 70mm thickness, ASTM F67 Titanium Bar, medical surgical implant titanium rod, astm f136 ti5al4v eli titanium bar, astm b348 grade 5 titanium bar