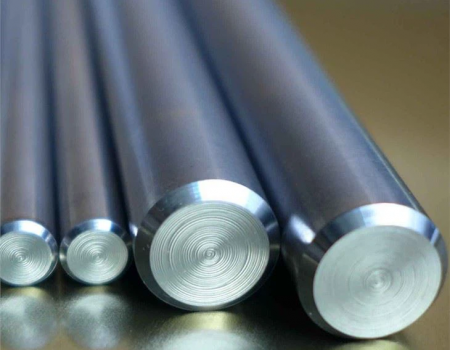

6al4v Titanium Rod has the advantages of both α and β titanium alloys, namely, good plasticity, good thermal strength (can work at 400°C for a long time), strong resistance to seawater corrosion, simple production process, and can be welded , Hot and cold forming, and can be strengthened by quenching and aging treatment. Mainly used in aircraft compressor discs and blades, naval pressure shells, large-size forgings, die forgings, etc.

6al4v Titanium Rod also has good low temperature performance. It still has good toughness below -196°C and is used to manufacture cryogenic high pressure devices, such as liquid hydrogen fuel tanks for rockets and missiles.

6al4v Titanium Rod is the nominal chemical composition representation method of titanium alloy grade TC4. Reference standard: "GB/T 3620.1-2007 Titanium and Titanium Alloy Grades and Chemical Composition". Main components: Al: 5.5%-6.75%, V: 3.5%-4.5%, the balance is Ti.

Chemical Composition

Tensile Requirements

Welcome to send an inquiry to mira@xjcmetal.com at any time if you need.

Sputtering-Target.44.1.png)