Titanium alloy rod is the strongest of all the titanium alloys thanks to its higher aluminum and vanadium content. It offers a versatile mix of good corrosion resistance, weldability, and formability.

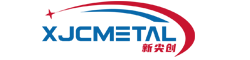

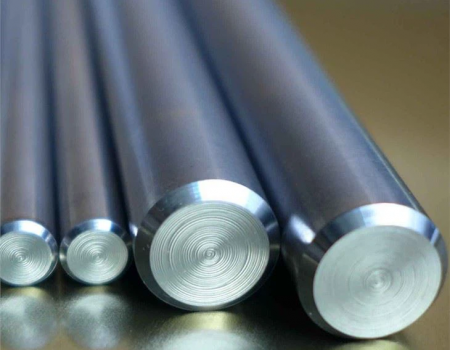

1.Specification: ф 2.0 ~ ф 300

2.Executive Standards: ASTM b348, ASTM F136

3.Type: polished titanium alloy rod, polished titanium alloy rod, black titanium alloy rod.

4.Delivery status: hot working status (R) cold working status (y) annealing status (m) solid solution status (st packaging: strapping or wooden box packaging)

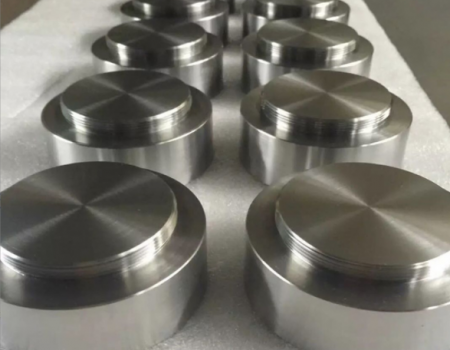

5.Surface treatment: polished or turned

6.Surface quality: high precision, good finish, no oxide layer, pockmark, crack, folding, rolling, scarring, delamination, hairline and other defects.

7.Surface finish: clean, dust-free, better acid resistant service life.

8.Physical properties: better elongation and strength properties.

9.Test: physical property test, hardness test, chemical composition test.

10.Features: 1. Low density; 2. High specific strength; 3. Resistance to acid, alkali, salt and seawater corrosion; 4. Superior mechanical properties.

11.Application: used in petroleum industry, electric power industry, seawater desalination industry, salt and alkali industry, coking industry, hydrometallurgy industry, pharmaceutical industry.

Titanium alloy is widely used in various fields because of its high strength, good corrosion resistance and high heat resistance. Many countries in the world have realized the importance of titanium alloy materials, and have carried out research and development on them one after another, and have been applied in practice.

Welcome to send an inquiry to mira@xjcmetal.com at any time if you need.